- [PDF]

THE KANBAN GUIDE

Kanban is a strategy for optimizing the flow of value through a process that uses a visual, pull-based system. There may be various ways to define value, including consideration of the needs of the customer, the end-user, the organization, and the environment, for example. Kanban comprises the following three practices working in tandem:

The Official Guide to The Kanban Method | Kanban University

Using the Kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. With the Kanban Method, you visualize invisible knowledge work and how it moves through a workflow.

The 6 Rules for Effective Kanban - Leanmantra

The Six Rules for Effective Kanban defined by Toyota are: Never pass on defective products. Take only what is needed. Produce the exact quantity required. Level the production. Fine-tune production. Stabilize and rationalize the process. Toyota Production System defined these 6 rules for themselves, so they could implement Kanban effectively.

Six Rules of Kanban: How to Better Implement Kanban

Mar 6, 2025 · The Six Rules of Kanban. Let’s explore the six rules of Kanban and how they both apply to traditional production and knowledge work. 1. Never Pass Defective Products. Upstream processes shouldn’t pass products that do not meet the standards and level of quality expected.

4 Core Kanban Principles & 6 Key Practices Explained - Teamhood

The 4 Kanban principles. The four principles of Kanban are: 1. Start with what you do now. Kanban recognizes the value of your existing processes and practices. At the start of any project, change management professionals will conduct a discovery phase to review and understand your current process.

Six Rules For An Effective Kanban System - Process Excellence …

Sep 21, 2010 · What are the Six Rules for an Effective Kanban System? To ensure a proper setup of Kanban in the workplace, Toyota has provided us with six rules for an effective Kanban system: Customer (downstream) processes withdraw items in …

4 Kanban Principles for Agile Project Management - Atlassian

Four core principles make up the Kanban framework: start with what you know, pursue incremental change, respect the current process, and encourage leadership at all levels.

Kanban Principles and Practices Explained - Kanban Software for …

Discover the essential principles and practices of Kanban for visualizing work, limiting WIP, and optimizing flow. Learn how to improve your team's efficiency and collaboration with these powerful techniques.

6 Core Kanban principles — and How to Apply Them - Miro

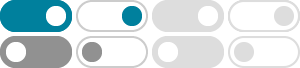

6 core Kanban principles. Whether you're just implementing Kanban or looking to improve your workflows, here are six core Kanban principles to keep in mind: 1. Visualize work. Visualizing work involves creating a clear depiction of workflow processes. Use Kanban boards to map tasks and stages visibly. This approach fosters transparency.

Kanban: Definition, 6 Rules, and its Benefits - Impact.

Jul 17, 2023 · Kanban is a method that makes work more visible and controllable. It helps companies identify inefficient business processes and find solutions. To implement Kanban effectively, follow the six rules mentioned in this chapter.