MATRIX VS PHASED ARRAY ULTRASONIC TESTING - Dolphitech

Explore the Differences Between Matrix Array & Phased Array Ultrasonic Testing Technology (UT) Methods for Accurate Non-Destructive Testing.

Single vs Dual Element vs Phased Array Probes | ScanTech

Apr 22, 2025 · In this guide, we’ll break down the three most common ultrasonic probes— single element, dual element, and phased array —and help you determine the best fit for your specific application. How They Work: These probes use a single piezoelectric crystal that both transmits and receives ultrasonic waves. Ideal Applications: Best-Fit Industries:

sided weld examination namely linear phased array tip diffraction technique, linear phased array third leg examination and Dual Matrix Array ultrasonic technique from probe placement at skew 270.

Dual Matrix Array for the Inspection of Acoustically Noisy Welds

An improved inspection method uses Olympus dual matrix array (DMA) probes and phased array ultrasound to electronically steer, skew, and focus acoustic beams through materials. Dissimilar and austenitic material welds are difficult to inspect using ultrasound.

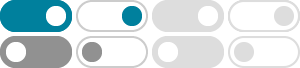

Phased-Array Ultrasonic Testing probes bring efficiency and flexibility for fast and accurate testing of various parts. Two-dimensional (2D) arrays offer very promising prospects as regards to flexibility (steering) and analysis (imaging) but currently suffer major drawbacks.

• Phased Array (PA) UT parameters applied were shown to be more effective for planar flaws, but slightly less effective for small volumetric flaws, versus RT • UT does not always provide a detectable response from both sides of a weld flaw during dual-sided access examination

Ultrasonic testing (UT) is a non-destructive testing (NDT) method used on Oil Country Tubular Goods (OCTG). Both conventional and phased array inspections provide near full-length coverage of tubular goods in accordance with American Petroleum Institute (API) specifications.

Designing a matrix array probe and predicting its performances and limitations is the first step for an inspection procedure qualification. To assess these performances, the French Atomic Commission (CEA) has developed for years semi-analytical models dedicated to UT.

Using Phased Array UT for Austenitic Weld Inspections

Jun 1, 2018 · Standardized dual 2D matrix array configurations can effectively cover the examination volume for stainless steel welds with the weld cap in place, and also allow the detection of planar and volumetric flaws.

Single Sided Weld Inspection using Advanced Ultrasonic Methods

Nov 22, 2015 · This paper considers a linear array probe as conventional phased array technology and a dual matrix array (DMA) probe as advanced phased array technology.